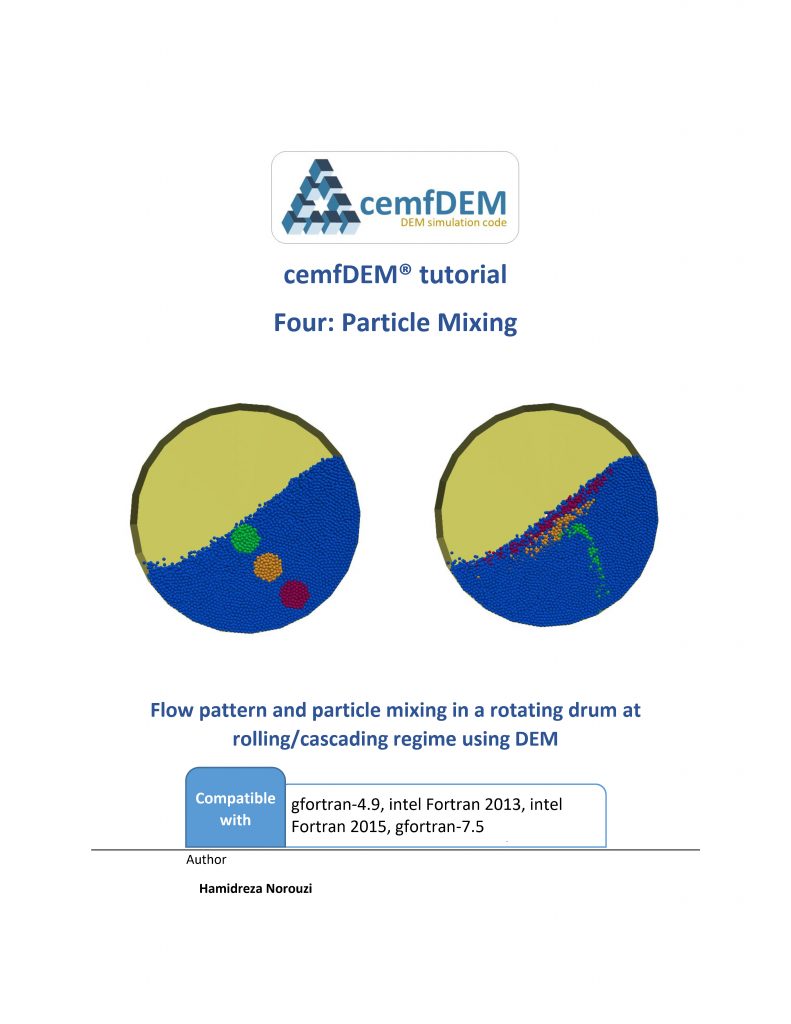

We investigate mixing mechanism in a rotating drum operating in rolling regime. To this end, a drum with the diameter of 0.2 m and depth of 0.03 m is half-filled with 19000 3-mm spherical particles. Rotation speed of the drum is 10 RPM. This rotation speed creates the cascading regime…