Granular flows are found in many processing units in various industries such as mining, food & pharmaceutical, and chemical. From all processing units, we can name some including various rotary and bladed mixers for blending particles with a wide range of properties, conveyors (mechanical or gas assisted) such as screw conveyors, bucket elevator and pipe conveyors for transporting particles, coaters and granulators such both drum-type and fluid bed-type, rotary kilns for cement and pyrolysis applications, coal and biomass combustion in various types of apparatuses. In all these processing units, we should understand the complex flow of particles for a better and improved design of the process.

In spite of fluids in our daily life (gases and liquids), solid flow behavior is much more complex, since shape of solid particles, in addition to the physical properties, completely change the bulk rheological behavior of the granular flow. That’s why we still don’t have accepted theories to describe their bulk behavior, as we do for fluid flows. So, the complex behavior of granular flow should be studied using a comprehensive model that accounts for all the necessary details related to shape and mechanics of solid particles.

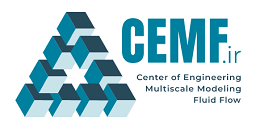

We in cemf use discrete element method (DEM) for simulating various granular flows. DEM models particles with their exact shape without any simplifications. In addition, the mechanical interaction between all contacting particles are modeled at particle scale. This model tracks the position and orientation of all particles in physical space and time. The result is a set of millions of ODEs that are solved simultaneously. This model can capture all the interactions at particle scales and hence can predict the main characteristics of granular flows due to changes shape, physical properties and operating condition.

To apply this model for industrial scale processes which millions of particles may involve in the simulation, efficient and flexible numerical codes that can solves this set of DOEs that contains millions of equations. We have been developing these codes since 2014 for DEM simulations. These codes can handle both spherical and non-spherical particles and simple to complex geometries with stationary walls / moving walls with complex motion pattern.

- To learn more about our DEM codes, visit this page.

- To see some sample output of these codes, visit this page.

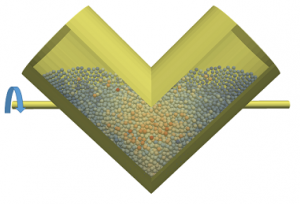

We also can couple DEM model with CFD equations for simulating two-phase flows involving solid particles. Some of the important two-phase flows are bubbling and circulating fluidized beds reactors, gas conveyors, Wurster coaters and granulators, and etc. For these applications we combined our DEM codes with OpenFOAM® capabilities to developed new solvers. These solvers can simulate multiphase flows with and without reactions.